General inquiries

info@arcternventures.com

Offices

Toronto, Canada

2 Bloor Street West, Suite 504

Toronto, ON, Canada, M4W 3E2

info@arcternventures.com

San Francisco, USA

Oslo, Norway

Rebel, 17th Floor

Universitetsgata 2, 0164 Oslo, Norway

Contact

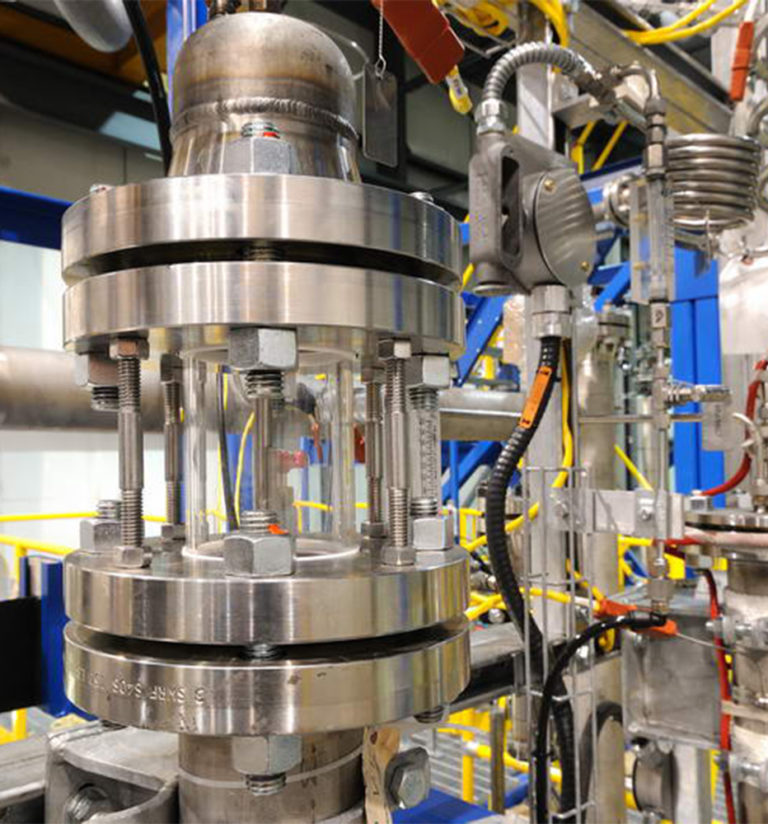

Woodland Biofuels

Cellulosic Ethanol Production

Woodland produces biofuel (ethanol) from waste biomass (non-food chain), lowering carbon content of transport fuels by ~92%. Woodland has refined a extensively patented process for converting a very high percentage of any biomass to syngas (or starting with reformed natural gas) and then to ethanol through a three stage thermo-catalytic process. Woodland currently operates a pilot plant in Southern Ontario and is in the process of building its first commercial facility that will be a low-cost producer of ethanol competing on cost with traditional gasoline producers.